Curved surfaces need special technology to print. Round shapes cannot be dealt with using flat printing. This problem can be addressed by using cylindrical screen printing. It enables clean printing of durable printing on round objects. It is a method that is used in many industries today. It provides predictable outcomes that are accurate. It is the printing process that applies to brands, as well as the labeling of the products.

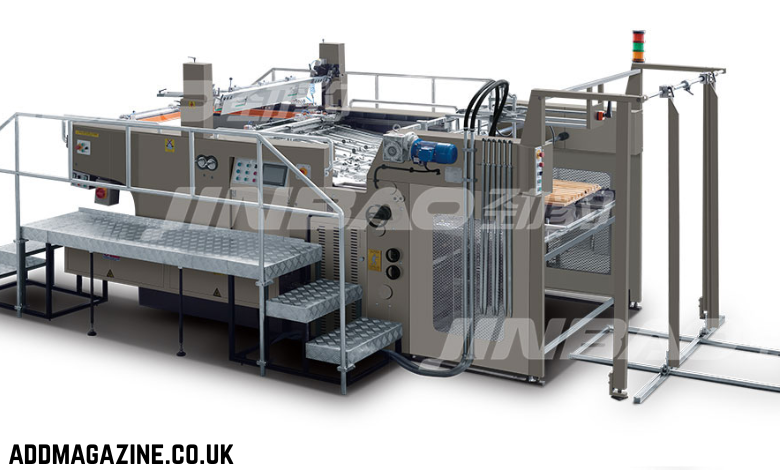

A Cylindrical Screen printing machine is a machine that is used on round products. It renders the even distribution of ink on curved surfaces. The characteristics of the designs printed remain clear and durable. This renders this machine suitable for industries. Its dependability and speed make it preferred by Manufacturers.

Slaughter a Slice. What is a Cylindric Screen Printing Machine?

An item known as a cylindrical screen printing machine is used to print designs on rounded objects. Such products are bottles, tubes, and containers. The machine operates by rotating the object when printing. The rotation causes ease in the transfer of ink over the surface. The style does not have holes or redundancy.

The machine is used to contain the design in a mesh screen. The ink is made to pass through the open portions of the screen. The ink is then transferred to the rotating object. The process produces sharp and clean prints. An effective Cylindrical Screen Printing Machine manufacturer provides machines for various production requirements.

Widespread products are printed on this machine.

Cylindrical screen printing is involved in many everyday products. This technique is used on smooth and uniform surfaces. It upholds different materials and sizes. It delivers quality output in industries. Most frequently printed products are the following items:

- Plastic and glass bottles

- Cosmetic tubes and jars

- Metal cans and containers

- Pharmaceutical packaging

- Pipes and cylinders in the industry.

Such products need bold and printable fonts. Cylindrical printing is such that it fulfils these quality expectations. The prints are not wearable or touchable.

Different Components of a Cylindrical Screen Printing Machine.

Every machine has many significant parts. All the parts work to the effect of printing. These parts are going to work together to determine the quality of printing.

The key elements consist of the following aspects:

- A rotary mandrel in which the cylindrical object is held.

- The frame is screwed to the screen, to which the printed design is further secured.

- A wipe that is made up of squeegee material pushes the ink through the screen.

- The ink system is the one that regulates the supply of ink.

- A drying unit that dries the ink.

These components are coordinated. This will guarantee homogeneous printing outcomes. The right alignment can be used to prevent ink smudging. Frequent maintenance enhances better performance of machines. Machine design is also a good way to get the precision of the print.

The functioning of a Cylindrical Screen Printing Machine.

The printing process has a proper order. The operator first puts the cylindrical object on the mandrel. The mandrel holds firmly to the object. When it is triggered, the object starts rotating smoothly. The screen is in the right place on the surface.

The ink is applied to the mesh of the screen. The squeegee would then roll through the screen. It is forced to enter through the open patterns. Simultaneously, the object turns in even measure. The ink flows within the entire surface through this movement. The object is sent out of the printing unit to the drying unit. The ink dries and makes it permanent.

The pros of the Cylindrical screen printing machine outweigh the cons.

The technique has many practical advantages for the printing method. It gives power prints, and they are durable. The inc produced on the surface is even. The technique is effective with other materials. It facilitates quick production as well.

The key advantages are the following points:

- Gives permanent and bright prints.

- Plastic, glass, and metalworks.

- Remains well covered in ink.

- Minimizes wastage of printing and reduces printing errors.

- Raises the overall production efficiency.

These strengths make this approach cost-effective. It is used by many manufacturers in mass production.

Cylindrical Screen printing machines are available as manual or automatic.

Cylindrical screen printing machines could be of either a manual or an automatic type. All these types have a distinct production need. Small-scale operations need manual machines. They also need operator control in the process. These workstations are cheap and simple to operate.

High-volume production is done through automatic machines. They are made with greater speeds. Human error is minimized by automation. An honest Cylindrical Screen Printing machine manufacturer can assist businesses in choosing the appropriate machine. The decision will be based on output requirements and budget.

Cylindrical screen printing is used in industries.

Cylindrical screen printing is used in many manufacturing processes. It assists in branding and identification of products. The approach has an excellent standard of quality. It also facilitates the durability of labels in the long run.

Some of the major industries that use this printing technique are the cosmetic, food packaging, pharmaceutical, chemical, and industrial manufacturing industries. Professional and correct printing is needed in these industries. Cylindrical objects make a decisive and appealing look.

Conclusion

The cylindrical type of screen printing machine is suited to print on round surfaces. It is an invention that incorporates rotation and screen technology. The process methods are used to provide the application of ink evenly and wearably. It is more reliable and quicker than alternative methods adopted by the industries.

Depending on selection of the correct machine enhances production. The choice of a reputable manufacturer of Cylindrical Screen Printing Machines would guarantee longevity. This printing technology is vital in contemporary industry printing.